The LiftMaster MH is a medium-duty hoist-style commercial door operator designed for reliability in mid-range usage. Part of LiftMaster’s medium-duty series, it is ideal for lighter commercial doors that see frequent use. This model caters to vertical or high-lift sectional doors as well as small rolling steel doors and grilles, making it a versatile choice for many businesses. In this review, we examine the MH’s performance, durability, safety features, installation, warranty, and door compatibility, drawing on expert articles and product analyses. We also summarize key pros and cons of the LiftMaster MH for commercial applications.

Performance Of LiftMaster MH

The LiftMaster MH is built around a ½ horsepower (HP) motor with a high-starting torque design for robust lifting power. It runs on standard 115V single-phase power and uses a capacitor start to ensure smooth, strong startup force. In practice, this motor delivers reliable operation for medium-duty needs – one supplier notes the MH is “renowned for its seamless operation” and efficiency. Users can expect quiet, smooth performance as well, thanks to LiftMaster’s engineering; the MH allows “seamless, quiet operation” even in busy work environments.

In terms of duty rating, the MH is intended for moderate daily cycles rather than continuous industrial use. It is rated for a maximum of 12 cycles per hour and up to 50 cycles per day. This duty cycle accommodates frequent operation throughout a typical business day, but exceeding 12 cycles/hour or ~50 cycles/day is not recommended, as it can shorten the unit’s longevity. In other words, the MH handles regular traffic reliably, but extremely high-frequency usage may warrant a heavier-duty model.

Notably, the MH 5011U model includes a Maintenance Alert System, which tracks usage and alerts when routine service is due. This feature helps maintain optimal performance and prevent unexpected downtime by prompting timely maintenance. The operator also has an integrated Timer-to-Close feature that can automatically close the door after a set interval (adjustable in 5-second increments, from ~5 up to 60 seconds). This ensures doors aren’t left open inadvertently, enhancing both security and energy efficiency. (One blog noted a 1–15 second auto-close range for a specific configuration, but the official specification allows up to 60 seconds.) Overall, the MH’s performance is characterized by dependable motor power and sufficient speed (approximately 8–9 inches per second travel speed) for most mid-size commercial doors, delivering consistent operation for its intended workload.

Durability Of LiftMaster MH

As a medium-duty commercial opener, the LiftMaster MH is engineered with solid build quality and components to ensure long-term resilience. The unit’s chassis features a heavy-duty 11‑gauge steel frame with a baked-on powder coat finish for durability and corrosion resistance. All drive reduction sprockets are drilled and pinned to their shafts, a robust design that prevents slippage over time. The drive mechanism itself uses a two-stage reduction: a first-stage heavy-duty V-belt and second & third-stage #48 roller chains, providing an efficient and durable transmission of power. Key moving parts are supported by heavy-duty oil-filled bushings, which offer good lubrication and wear resistance for extended life.

The MH’s motor and drive system include protective features to enhance longevity. It has an adjustable friction clutch that will slip when the door encounters an obstruction, protecting both the door and the opener from damage due to jams or binding. This clutch acts as a safeguard against excessive force, reducing strain on the motor and hardware. Additionally, a built-in motor overload protection will cut power if the motor overheats or is overworked, preventing burnout during demanding operations. These features reflect a focus on durability – the operator is designed to “withstand the test of time” in a commercial setting.

Other construction details also speak to its resilience. The solenoid brake is a heavy-duty component that not only securely holds the door in place when stopped, but also is built for longevity under frequent use. The MH’s modular design allows the motor to be removed without disturbing the limit switch settings, which simplifies servicing and minimizes downtime during maintenance or repairs. Industry commentators have praised the MH5011’s build, calling it “robust” and highlighting its “excellent durability” in the field. In summary, the LiftMaster MH’s sturdy construction and protective design features make it a durable operator suited for medium-duty commercial demands. Properly used within its duty limits, it should provide years of reliable service in busy yet not extreme environments.

Safety Features Of LiftMaster MH

Safety is a critical aspect of any commercial door operator, and the LiftMaster MH includes a comprehensive set of built-in protections and adheres to industry standards. Importantly, the MH meets UL 325 safety standards, indicating it has the required safety provisions to prevent entrapment and injury. The operator comes standard with LiftMaster’s Commercial Protector System® photo-eye sensors (model CPS‑U). These infrared safety sensors project a beam across the door opening and will instantly stop and reverse the door if an obstruction (a person, vehicle, or object) breaks the beam while the door is closing. This prevents the door from closing on people or property in its path. The system’s sensing technology will also halt closing if the door physically contacts an object, as an additional fail-safel. The photo-eyes are monitored, meaning the operator’s logic will detect if the sensors are disconnected or malfunctioning and, if so, default to a safe mode (e.g. requiring constant-pressure to close) to avoid unsafe operation.

Beyond the photoelectric sensors, the MH provides other layers of safety and protection. It is equipped with a 90-second maximum run timer that will cut power if the door doesn’t complete its travel within 90 seconds. This prevents the motor from running indefinitely in case of a mechanical problem or jam, reducing the risk of overheating or fire. The earlier-mentioned friction clutch also serves as a safety device by slipping if the door is obstructed, thus avoiding excessive force on the door or any object in its way. Likewise, the solenoid brake engages to hold the door in position and can help stop the door quickly when needed, contributing to safe and controlled operation.

For emergency situations or power loss, the LiftMaster MH includes a manual chain hoist with an electric interlock. This means users can pull a disconnect chain to switch the operator to manual mode and open the door by hand. The electric interlock ensures that when the manual hoist is engaged, the motor is electrically disabled, preventing any chance of the motor unexpectedly starting. This feature is invaluable for safely operating the door during power outages or if the operator fails – one can manually lift the door via the chain without fear of electrical backdrive. A floor-level disconnect is provided for quick access to this hoist in emergencies.

From a security standpoint, the MH is equipped with LiftMaster’s Security+® rolling code receiver on 315 MHz. Every remote activation sends a new code from billions of possible combinations, which prevents code theft and unauthorized duplication of the remote signal. While not a safety feature in the entrapment sense, this adds to the overall secure operation of the door, protecting against intruders accessing the garage or building.

In summary, the LiftMaster MH provides robust safety features expected in a commercial operator: compliance with UL 325, required photo-eye sensors, timed auto-reverse on obstructions, motor overload and run-timer protections, and a reliable emergency manual operation system. These features work together to ensure the door operates safely for personnel and property. (As always, professional installation and regular testing of these safety systems are advised to maintain compliance and effectiveness.)

Installation Of LiftMaster MH Manual:

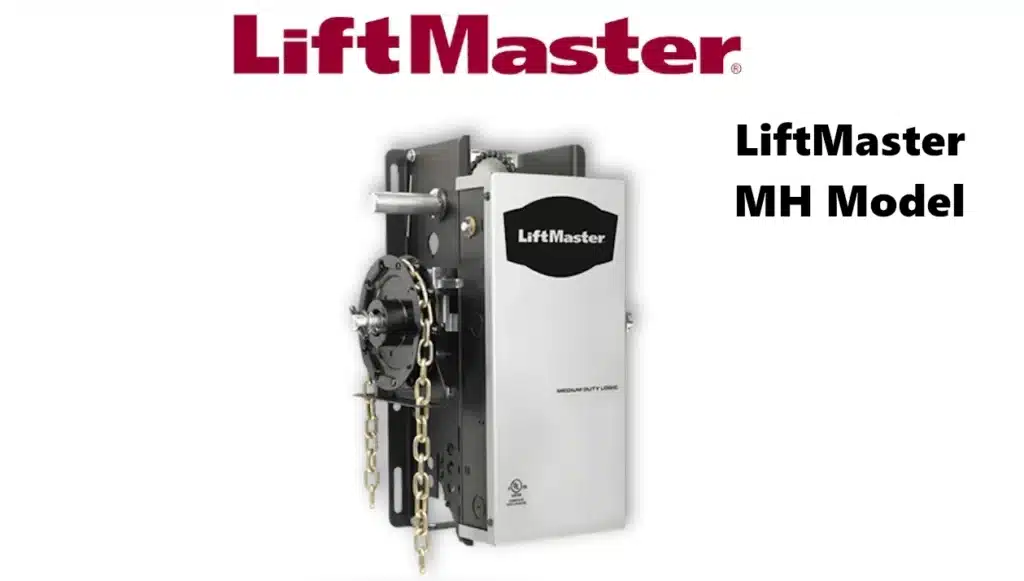

Installing the LiftMaster MH is generally straightforward for trained professionals, and the unit is designed for flexible mounting to fit various door setups. It is a jackshaft (wall-mounted) hoist operator, which mounts to the side of the door at the torsion shaft (as opposed to a ceiling-mounted trolley). The MH can be mounted on either the left or right side of the door shaft, providing flexibility to accommodate site conditions or obstructions. A blog article notes that “installation is easy, all you have to do is mount it on the wall and attach it to the door shaft through the chain and sprocket”, thanks to the hoist design. The package includes the necessary chain sprocket hardware to connect the operator to the door’s torsion tube. Once physically mounted and aligned, the limits and force settings can be adjusted for optimal travel and stopping accuracy.

The MH requires at least 18 inches of side clearance beside the door opening for proper mounting space. This is usually available on high-lift or vertical-lift doors where the track runs upward, but should be checked in advance. (For very tight side room situations or low headroom doors, a different operator style might be needed.) The unit weighs on the order of ~70 lbs, so handling during installation may require two people or equipment for safety.

Wiring the MH involves connecting it to a suitable power source (115V AC) and hooking up the control station and safety sensors. The operator features a solid-state medium-duty logic control board that comes pre-wired to accept the photo-eye sensors and includes terminals for the wall-mounted 3-button control station. Type C2 wiring is standard (constant-pressure-to-close without safety devices), but by installing the provided photo sensors the system can be set to UL Type B2 mode (momentary contact to close with functional safety devices). For most installations, the included three-button control station (Open/Close/Stop) is wired to the operator for local control. The integrated radio receiver can learn up to 20 remote controls for wireless operation as well.

While a skilled DIYer with commercial door experience might follow the manual, professional installation is highly recommended. LiftMaster notes that commercial door operators are complex and should be installed and adjusted by qualified technicians. A professional will ensure that the hoist is properly aligned, the door is balanced with adequate springs, the limits and force settings are correct, and all safety features are tested for compliance. Proper installation not only affects performance but also longevity and safety (e.g. torque on the torsion shaft must be set correctly, and photo-eyes aligned). In the event of any issues, having a dealer-installed unit typically makes warranty support easier as well. The good news is that LiftMaster has an extensive dealer network, so support and installation expertise are readily available in most areas.

Once installed, daily operation is user-friendly. The MH’s chain hoist allows for easy manual use when needed, and its electronic controls (including the timer-to-close and maintenance alert) operate in the background to simplify usage. Overall, installers and users find the MH versatile and relatively simple to set up on the appropriate door types, with the caveat that it should be installed to manufacturer specifications for safe and optimal performance.

Door Compatibility Of LiftMaster MH Model

The LiftMaster MH is designed to work with specific types of commercial doors, primarily those that are smaller in size or weight and configured for jackshaft operation. According to product documentation, the MH is “for use on vertical or high-lift sectional doors, or small rolling doors and grilles.” In practical terms, this means it is well-suited for:

- Sectional overhead doors that have a high-lift track or full vertical lift track (common in warehouses where the door travels upward along the wall).

- Rolling steel doors or grilles that are small to mid-sized (such as counter shutters, storage roll-ups, or security grilles).

These types of doors have their barrel or torsion shaft mounted at the top (or high on the wall), which the MH can attach to directly. The operator’s hoist mechanism turns the shaft to raise or lower the door.

However, the MH is not intended for all commercial door sizes and types. For example, extremely large or heavy rolling steel doors (e.g. full-size industrial service doors) would likely exceed the MH’s medium-duty capacity and would require an industrial-duty operator (LiftMaster’s heavier models like J, H, or GH series). Likewise, the MH is not the typical choice for standard-lift sectional doors that have horizontal tracks along the ceiling – those often use trolley-type operators (or a different jackshaft model if adapted) for optimal operation. While the MH could technically be used on a balanced standard-lift sectional door with a torsion spring (and in fact LiftMaster’s similar jackshaft models are sometimes used in residential garages), it’s generally recommended for the vertical/high-lift scenarios. The manufacturer emphasizes the MH is meant for “smaller, lighter commercial doors” with moderate duty requirements.

In terms of size limits, there isn’t a one-size-fits-all dimension spec publicly given, but dealers often list compatibility up to certain door heights or areas. For instance, one vendor configuration allowed selecting door heights from 7 ft up to 16 ft for the MH operator. This suggests the MH can handle door heights in that range, assuming the weight is within a medium-duty range and properly counterbalanced. The weight capacity isn’t explicitly stated, but “medium weight or moderately heavy” doors are mentioned as the target. As a rule of thumb, if a door is well-balanced (springs calibrated) and does not exceed the cycle rating and motor torque of the MH, it should work. If a door is exceptionally heavy or used nonstop, a heavier-duty (or higher horsepower) operator would be advised.

In summary, door types compatible with the LiftMaster MH include:

- Vertical-lift sectional doors (common in industrial warehouses).

- High-lift sectional doors (often found in commercial garages needing extra overhead clearance).

- Small rolling steel doors and rolling grilles (such as security shutters, smaller service doors).

Door types or scenarios not ideal for the MH:

- Very large or heavy doors (use an industrial-duty opener instead).

- Continuous duty high-traffic doors (exceeding ~50 cycles/day regularly).

- Standard lift sectional doors with low headroom (a trolley operator or different jackshaft might be more appropriate, though case-by-case).

By choosing the MH for the right door application, users will get the best performance and lifespan. Using it within its intended scope – medium-duty, smaller commercial doors – will ensure it operates safely and efficiently for years. If there’s any doubt about compatibility, consulting a LiftMaster dealer or referring to LiftMaster’s door operator selection guide is recommended, as they can confirm if the MH is a fit or if another model is better suited.

Warranty and Support Of LiftMaster MH

LiftMaster backs the MH operator with a limited 2-year warranty, which is fairly standard for commercial door openers in this class. This warranty covers defects in materials and workmanship for the first two years from the date of purchase. In practical terms, that means if the unit fails due to an internal defect (and has been installed and used according to specs), LiftMaster will repair or replace the affected parts/unit within that period. It’s worth noting that like most warranties, it does not cover issues caused by improper installation, misuse, lack of maintenance, or normal wear items. For example, damage from a door that is not properly maintained (springs, hardware issues) wouldn’t be covered.

Manufacturer support for the MH is typically provided through authorized LiftMaster dealers and the company’s customer service channels. Since LiftMaster (by The Chamberlain Group) sells commercial operators primarily via dealers, your installer usually handles any warranty claims or repairs. Users can contact LiftMaster’s commercial tech support line for assistance, but often a certified technician will be dispatched for on-site service if needed. The dealer network is a strong point – LiftMaster has many qualified dealers and service centers across regions, so obtaining service or replacement parts (even beyond the warranty period) is generally convenient. Additionally, the MH shares many components with LiftMaster’s medium-duty line, meaning parts like circuit boards, sensors, and brake/clutch components are readily available.

The 2-year warranty is inclusive of the entire operator (motor and parts). Some competing or heavier-duty models might offer longer warranties on certain components (for instance, 5 years on motor/gears), but for a medium-duty unit, two years is a solid coverage period. It indicates the manufacturer’s confidence in the product’s quality while aligning with the expected commercial usage. Users have commented that LiftMaster openers, in general, have long operational lives when maintained, often well beyond the warranty term. The support and parts availability from LiftMaster further ensure that even after warranty, the MH can be serviced to extend its life.

In summary, the LiftMaster MH comes with a two-year warranty for peace of mind. Backed by LiftMaster’s reputable customer support and dealer service infrastructure, owners can expect reliable assistance for any issues that arise, whether under warranty or for routine maintenance. Be sure to register the product (if applicable) and keep proof of purchase, and always have a professional address any problems to remain eligible for warranty coverage.

Pros and Cons Of LiftMaster MH

To distill the key points, here are the notable advantages and drawbacks of the LiftMaster MH model:

Pros:

- Reliable Medium-Duty Performance: Proven LiftMaster P3 motor technology (½ HP) with high-start torque delivers dependable operation for mid-level commercial use. The unit runs smoothly and is engineered for quiet, efficient door movement.

- Durable Build Quality: Sturdy 11-gauge steel frame, heavy-duty belt and chain drive, and oil-filled bushings contribute to long-term durability. Protective features like the friction clutch and motor overload safeguard the opener and door, enhancing longevity.

- Comprehensive Safety Features: Fully UL 325 compliant with included photo-eye sensors that stop/reverse on obstructions. It also has a solenoid brake for secure stops, a 90-second run timer, and an emergency chain hoist with interlock for manual operation. These ensure safe operation and meet commercial safety standards.

- Versatile Installation: Can be mounted on either side of the door and is suitable for various door types (vertical-lift, high-lift, small roll-ups). The design frees up ceiling space (wall-mounted), and installation is straightforward for professionals. The maintenance alert system and adjustable settings make it user-friendly to set up and service.

- Warranty and Brand Support: Backed by a 2-year warranty and LiftMaster’s strong dealer network, giving buyers confidence in after-sales support. LiftMaster’s reputation as a trusted brand in door operators adds peace of mind.

Cons:

- Limited Heavy-Duty Capacity: With a 12 cycles/hour, 50/day duty rating, the MH is not meant for very high-cycle or extremely heavy doors. Businesses with constant door operation (e.g. high-traffic loading docks) or oversized doors may find it underpowered or may shorten its lifespan by overuse. In such cases, an industrial-duty model would be more appropriate.

- No Smart Connectivity: Unlike some modern LiftMaster products, the MH lacks built-in Wi-Fi/MyQ connectivity for smartphone control. It cannot be directly monitored or operated via the MyQ app without additional external adapters (and even those may not be supported). This is a drawback for users who desire remote access or integration into smart building systems.

- Medium-Duty Only: While well-built, it’s still a medium-duty operator – some heavy-duty features of costlier models (e.g. higher HP motors, continuous-duty cycle, or advanced logic features) are not present. For instance, it’s not as fast or strong as larger LiftMaster industrial operators, and it’s not compatible with certain accessories like MyQ or some advanced control options due to its Medium-Duty Logic board.

- Specific Door Type Requirement: The MH is intended for specific door configurations (high-lift, vertical, small roll-up). If a facility has standard lift sectional doors with limited side room, using the MH might require modifications or may not be ideal. In those scenarios, a different model (e.g. a trolley operator like the LiftMaster MT series) could be a better fit. In short, the MH’s versatility does not extend to every commercial door type.

- Cost vs. Light-Duty Options: The MH is more robust (and typically pricier) than “light-duty” commercial or top-end residential openers. If a door only sees very infrequent use or is very small, the MH might be overkill where a lighter-duty, less expensive opener could suffice. Conversely, if a business tries to save cost by using an MH where a heavier-duty is needed, it could lead to more costs later. It’s important to match the operator to the application.

Medium-Duty Jackshaft Operator by LiftMaster – Quick View

The LiftMaster MH medium-duty hoist operator proves to be a solid choice for commercial applications that require a balance of reliability, safety, and moderate duty performance. It shines in scenarios with mid-weight doors and periodic, frequent cycling – such as small warehouse doors, commercial shop doors, or security grilles that open and close throughout the workday. The MH delivers operational reliability and consistent power, backed by a suite of safety features (UL 325 compliance, sensors, clutches, and brakes) that inspire confidence in daily use. Its build quality – heavy-gauge steel, quality drivetrain components – suggests it can handle the rigors of a busy environment while remaining dependable over time.

That said, prospective buyers should ensure their use-case aligns with the MH’s intended scope. For demanding high-cycle or oversized doors, a heavier-duty model in LiftMaster’s lineup would be better suited to avoid pushing the MH beyond its limits. Additionally, those who value modern smart controls must note the absence of built-in MyQ connectivity on this model. Within its niche, however, the LiftMaster MH earns praise from installers and users alike for combining ease of installation, robust safety, and reliable performance. Supported by LiftMaster’s warranty and dealer support, the MH offers commercial customers a dependable mid-range door operator that can serve their business for years with proper maintenance.

In summary, the LiftMaster MH is a well-rounded medium-duty opener – it stands out for its durability and safety in operation, and while it has some limitations (duty cycle and lack of smart tech), it capably fulfills the needs of many commercial door applications. By considering the points above, businesses can determine if the MH aligns with their door’s requirements and appreciate the value it brings as a quality commercial door operator in the LiftMaster family.