“When a garage door suddenly veers off its track, it’s often because one of two critical components has failed: the lift cables or the drive chain. Both are under high tension and work alongside torsion or extension springs to lift a door weighing hundreds of pounds. If they wear out, seize, or break, the result can be violent — doors slamming, twisting, or falling. This is a primary cause covered in our guide on how to fix a garage door off track, including costs and track alignment tips, where bent tracks and rollers popping out create dangerous conditions. Understanding how these parts function and recognizing their warning signs can prevent expensive repairs and serious injuries.”

The Critical Role of Cable Tension

Garage‑door lift cables run from the bottom brackets of the door to drums mounted near the torsion spring. They counterbalance the door’s weight so that the opener doesn’t carry the entire load. Proper tension keeps both sides lifting evenly; when one cable is tighter or looser than the other, the door tilts and strains one side of the track. Over time, this imbalance can lead to frayed cables, bent tracks or broken springs, and in severe cases the door may jam or fall unexpectedly. Because cables and springs work together, technicians adjust tension on both sides simultaneously during maintenance to maintain balance.

Snapped Cable Failure

A snapped cable is a major mechanical failure. When one cable breaks, the entire weight of the door transfers to the remaining side. According to garage‑door repair experts in Florida, a broken cable leaves the door unbalanced, harder to operate and potentially unsafe. Without both cables functioning, the door will likely tilt or come off balance, which can damage the tracks and rollers. The heavy, uneven load may also stall the opener or cause the door to get stuck mid‑travel. Professionals warn that a snapped cable may cause the door to drop violently, slamming shut and putting anyone nearby at risk. For this reason, homeowners should never attempt to lift or use a door with a broken cable; the opener and springs cannot safely handle the imbalance.

The Twisting Effect

If a cable fails while the opener is running, the door may twist as the motor continues pulling on only one side. A blog on garage‑door balance notes that a door that pulls to one side can twist the track or damage the opener motor; such repairs are more costly than correcting the balance. Similarly, garage‑door technicians report that when a frayed or weakened cable fails, the sudden shift in tension can force the door to slam shut or hang awkwardly, and the imbalance strains the opener and bends track components. In severe cases, the twisting force can cause rollers to pop out of the rails. Regular tension checks and replacing worn cables before they snap are critical to avoid these sudden, violent failures.

The Chain Reaction

Because the two cables work together, a broken cable causes a domino effect. When the door hangs crookedly, gravity and the opener exert extreme lateral pressure on the rollers and tracks. Garage‑door professionals explain that a cable jump — when a cable rolls off its drum — misaligns the door, causing it to become cockeyed; this misalignment can cause rollers to pop out and tracks to bend. Calgary‑area experts add that if one cable becomes tighter than the other, the door can tilt or strain one side of the track, potentially leading to frayed cables, bent tracks or broken springs. Another safety warning notes that when a cable snaps under tension, the entire load shifts to the other side, often throwing the door out of track and necessitating a more complex repair. To prevent such chain reactions, both cables should be inspected regularly and replaced in pairs so that tension remains balanced.

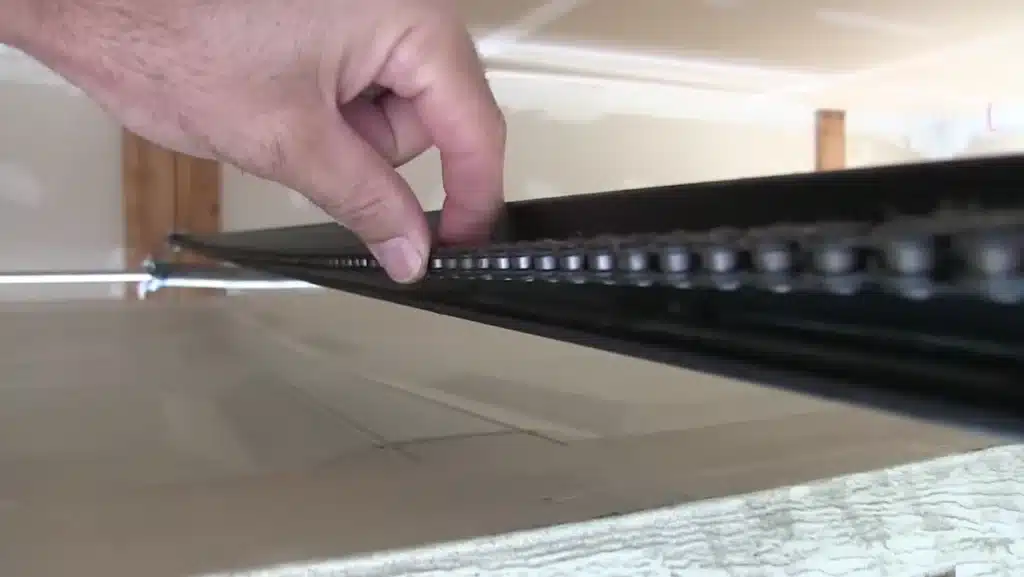

Chain and Drive‑System Malfunctions

Chain‑drive openers use a metal chain looped around a sprocket on the motor and along a rail to pull the trolley. When this chain is slack, bunched or worn, it can jerk the door or slip off the sprocket, leading to off‑track problems.

Chain Slack and Bunched Links

A properly tensioned chain should sag only about half an inch; if it hangs lower, homeowners may notice visible sagging and unusual noises such as rattling or slapping. Garage‑door guidance notes that a loose chain often causes jerky or inconsistent door movement, which can be dangerous. As slack increases, the chain may slip off the sprocket altogether. A 2025 guide on loose garage‑door chains warns that sagging puts stress on the motor and can cause the chain to jump off the sprocket, risking a sudden drop. It also points out that chains may look stretched or show gaps between links, and if tightened repeatedly yet still loosen back up, replacement is a safer option. Bunched links or chain rub against the cover or track, creating jerks that can pop rollers from the channel. Regularly checking chain tension and lubricating the chain can prevent these issues.

Sprocket Failure

The chain wraps around a sprocket gear on the opener motor. Worn sprocket teeth or a damaged sprocket can cause the chain to jump or slip, leading to sudden drops or door slamming. In a list of “don’t ignore this” signs, garage‑door technicians warn that if the sprocket teeth are worn down or missing, it’s safer to replace the opener or chain system. They emphasize that chains typically last 10–15 years, but an opener older than eight years with noisy or inconsistent operation may have a failing sprocket. When the chain jumps due to a stripped or broken sprocket, the door can fall or slam, potentially derailing the vertical tracks and damaging panels. To avoid this hazard, any sign of a worn sprocket — grinding noises, chain rubbing the cover or visible tooth wear — should prompt a professional inspection.

Warning Signs of Impending Cable Failure

Cables rarely fail without warning. By inspecting the cables and listening to the door’s operation, homeowners can catch early signs of danger.

Frayed Steel Strands

The most obvious warning is visible fraying. If wire strands are poking out or wrapped loosely around the drum, the cable is on borrowed time. A guide to cable replacement stresses that frayed cables are urgent; they can snap at any moment and cause sudden door drops or serious injury. Another maintenance article notes that fraying metal strands, rust spots or kinks along the cable’s length are early signs of uneven tension. Inspecting cables regularly — especially near the bottom bracket where the cable winds around the drum — allows you to spot broken or fuzzy strands. If fraying is visible, do not use the door until a technician replaces the cable.

Corrosion at the Bottom Fixture

Moisture and salt at the base of the door can cause rust on the cables and bottom bracket. A late‑summer warning from Texas garage‑door specialists explains that humid coastal air and storms accelerate corrosion on metal cables. It lists visible rust spots or pitting near the bottom bracket or drum as a key indicator that a cable is failing. Overhead Door experts add that strange noises or friction can be tied to rust or a lack of lubricant on the cables; if left unchecked, this friction can damage the gear assembly or bottom bracket. Keeping the area clean and dry and applying lubricant reduces corrosion risk. If you see rust or pitting where the cable attaches, schedule a professional inspection; corrosion weakens the steel and is a common point of total failure.

Slack Cables

Cables should remain taut even when the door is closed. Slack or dangling cables near the bottom bracket are a red flag. Overhead Door warns that loose cables throw the entire system off balance, leading to misalignment, drum damage or even a complete door failure. The Texas maintenance guide likewise lists slack cables when the door is closed as a sign that the system is compromised. Another warning notes that a sagging loop near the bottom bracket indicates slack that should not be there; scraping or popping noises may occur as the cable rubs misaligned parts. If you notice slack, stop using the door immediately. Professionals can assess whether the issue is due to a stretched cable, worn drum grooves or a spring problem.

Proactive Inspection and Professional Repair

Lift cables and drive chains may seem like small components, but they bear the brunt of the work in a garage‑door system. When cables snap or lose tension, the door can twist, slam shut, or tilt off its rails — causing bent tracks, popped rollers and dangerous conditions. A slack or bunched chain can jerk the door and slip off the sprocket, leading to a sudden drop.

Fortunately, these failures usually give advance warning: frayed steel strands, rust near the bottom bracket, slack cables, jerky movements, unusual noises and chain sagging. Performing regular visual inspections and listening for changes in the door’s operation can prevent catastrophic off‑track events. If you notice any of these warning signs, don’t wait for a total failure—contact a specialist for emergency garage door repair near me to ensure your system is safe and balanced.