Garage‑door tracks look like simple pieces of curved metal, yet they are precision‑engineered channels that guide a 150–400‑lb door up and over your head. When a track is dented or creased, the door may stop, jam or even fall, If you aren’t sure if the track is the main issue, start by Identifying a Garage Door Roller or Wheel Off Track. making repairs a critical safety issue. This guide explains how to decide whether a minor bend can be tapped out with a rubber mallet or whether the track has reached a point of no return and needs replacement.

1 – The “Integrity First” Rule

1.1 How a bent track loses strength

Garage‑door tracks are typically made from galvanized steel. Steel is tough, but it gains its strength from a uniform grain structure. Once a section is plastically deformed (permanently bent), its load‑bearing capacity drops. Materials scientists note that plastic deformation “can reduce the effective load‑bearing capacity by diminishing both strength and stiffness in the affected region”. Put simply, once the metal has been creased or pinched, it behaves like a dented soda can—no matter how you reshape it, the metal around the crease has been stretched and will never be as strong as before.

1.2 Why bending back can cause hidden failures

Many homeowners try to pound a damaged track back into shape. While a light tap might improve the appearance, track manufacturers and professional installers warn that bent steel rarely recovers its original strength. CaliforniaGarageDoorRepair’s track‑alignment guide stresses that bending a track back into shape “weakens the metal and often causes hidden cracks”; therefore any visibly bent or kinked track should be replaced. Hidden cracks or stress risers can suddenly fail under the door’s weight, leading to a catastrophic collapse. For that reason, the golden rule is:

If the metal is creased, kinked or cracked, replace the track. Never rely on a “re‑straightened” rail to carry a heavy door.

1.3 Signs your track’s structural integrity is gone

A track may look “mostly straight” yet still be unsafe. Common red flags include:

- Deep creases or folds in the channel walls. These creases indicate plastic deformation. Because the metal was stretched beyond its elastic limit, the creased section is permanently weakened.

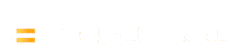

- Kinks or twists in the curved radius (where the vertical rail transitions to horizontal). The radius is carefully bent to a 12‑ or 15‑inch curve so the door glides without binding. A twist or flattening in this area will cause the rollers to jam and cannot be safely repaired.

- Splits or sheared metal around mounting holes. Stripped or torn bolt holes mean the track can no longer be securely anchored; replacement is the only safe fix.Severe corrosion at the bottom six inches or where the track meets the floor . This is a primary cause of The 6-Inch Stall: Troubleshooting a Bent Garage Door Track, where the door stops almost immediately after opening. . Ingstrup Garage Doors notes that rails exposed to moisture can become rusted or corroded, and when you see rust or corrosion on your rollers or rails, they “should be replaced as soon as possible to avoid further damage”.

2 – When You Can Hammer: Minor Fixes

Not every blemish warrants a new track. Cosmetic bends and flared edges can be repaired if they do not distort the C‑channel and the metal has not been creased. Here are situations where DIY hammering is acceptable:

2.1 Flared lip

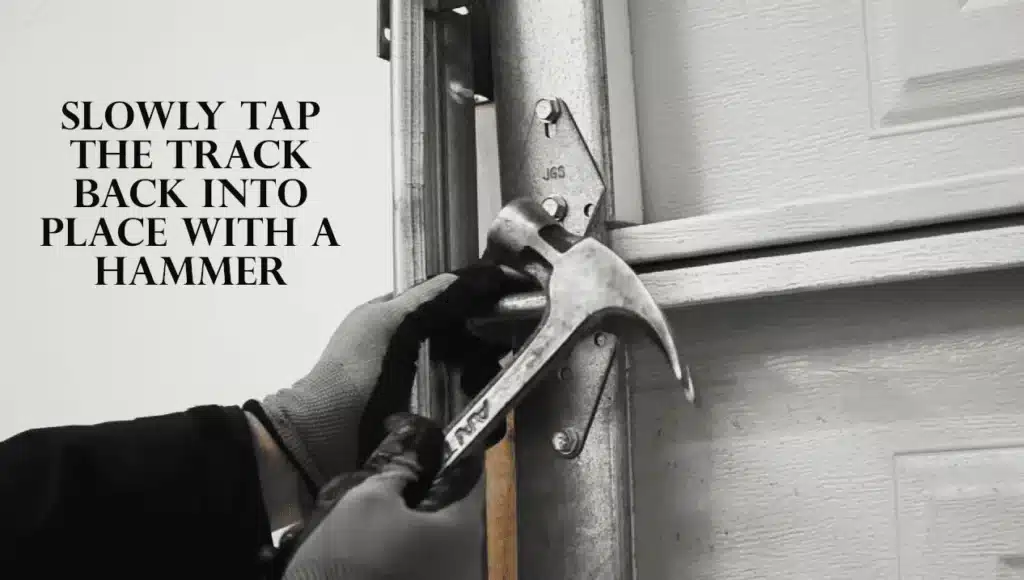

The most common minor damage is a flared outer lip—the thin edge that guides the roller into the track. A roller that jumps the rail can bend this lip outward. As long as the channel itself is straight, you can gently tap the lip back using a rubber mallet or a hammer with a wood block. Using wood spreads out the force so you don’t dent the track or crack the protective zinc coating. A rubber mallet is soft enough to adjust the flange without damaging the metal.

2.2 Minor dents or shallow curves

Small indentations that do not narrow the channel can also be coaxed back. FixMyGarageDoor’s step‑by‑step guide emphasizes that successful repairs require “finesse, not force.” After loosening the hardware and securing the door, they recommend using pliers or a rubber mallet with a block of wood to gently straighten the bend, distributing the force to avoid further damage. Check your progress with a level; the goal is to restore the original geometry without creasing the metal.

2.3 Surface scrapes and paint damage

Cosmetic scrapes or small dents in the side of the track do not affect door operation. Touch up any bare metal with galvanized paint to prevent rust, but there’s no need to hammer if the rollers glide smoothly.

2.4 Tools and tips for minor fixes

- Locking pliers or C‑clamps: Before working, clamp the door to the track above the lowest roller to keep it from dropping. Both FixMyGarageDoor and R&S Erection of Richmond emphasise securing the door with C‑clamps or locking pliers to prevent sudden movement.

- Rubber mallet and wood block: Use a mallet or a hammer with a block of wood to tap the track back into alignment. Never hit galvanized steel directly with a metal hammer; you’ll crack the zinc coating and invite rust.

- Wrench/socket set: Loosen the mounting bolts slightly to allow the track to move. Tighten them once the rail is straightf.

- Level: After straightening the lip, you must ensure the entire rail is positioned correctly. Follow our guide on How to Safely Re-align Tracks to restore perfect vertical balance.

- Lubricant and cleaning supplies: After the repair, clean the track and apply a light silicone‑based lubricant to the rollers (not the track) to ensure smooth motion.

If the track looks straight and the door runs smoothly by hand after these steps, you’ve saved yourself the cost of a new rail. If the door still binds or drags, move on to replacement.

3 – When You Must Replace: The Danger Zone

Certain types of damage compromise the track’s structural integrity or geometry so severely that replacement is the only safe option. Continuing to hammer or adjust these issues will only delay an inevitable failure.

3.1 Warped or twisted radius

The curved section (usually a 12″ or 15″ radius) allows the door panels to transition from vertical to horizontal without twisting. If this curve is flattened, kinked or twisted, the rollers will bind or pop out. Because the radius is precision‑engineered, there is no way to re‑bend it accurately in the field. Replace the entire curved section.

3.2 Sharp creases or folds

A “crease” is a sharp fold in the metal, often caused by a car hitting the track or the door slamming against an obstruction. The crease stretches and weakens the steel; pounding it flat will hide the damage but not restore strength. CaliforniaGarageDoorRepair warns that “bending garage door tracks back into shape weakens the metal and often causes hidden cracks,” and they recommend replacing any bent or kinked section.

3.3 Corrosion and rust

Moisture, road salt and winter slush can eat away at the lower portion of vertical tracks. Ingstrup Garage Doors notes that rails exposed to moisture may become rusted or corroded, and when you notice rust or corrosion on your rails, you should replace them as soon as possible. Rust thins the metal, weakening the anchor point where the track attaches to the jamb. If more than superficial surface rust is present—especially in the bottom 6–8 inches—replace the track.

3.4 Gaps, splits and stripped mounting holes

Split seams or cracked welds indicate metal fatigue. Likewise, if the bolts no longer hold because the mounting holes are enlarged or torn, the track cannot be secured properly. Replace the track and hardware together.

3.5 Multiple bends or long damaged sections

FixMyGarageDoor advises inspecting the entire track before deciding on a repair. If the track is bent “in several places or over a long section,” a simple fix may not be enough and replacing the damaged section entirely is safer and more effective. Attempting to repair severe damage can weaken the metal further, causing repeated failures.

4 – The “Clunk” Test and Other Diagnostics

Even before you grab your tools, there are simple ways to determine whether you’re dealing with a minor tweak or a serious defect.

4.1 Visual inspection

- Check for gaps: With the door closed, shine a flashlight along both rails. The rollers should ride snugly in the channel with no daylight visible between the roller and the track. A gap indicates a warped track.

- Look for twist or lean: Use a level to confirm that the vertical sections are plumb and the horizontal sections are level. CaliforniaGarageDoorRepair highlights that uneven or tilted tracks cause roller drag and opener strain.

- Inspect hardware: Examine the jamb and flag‑bracket bolts. Loose hardware can make the track wiggle, eventually allowing rollers to jump out. Tighten these bolts but never loosen spring anchors or cable drums.

4.2 Sound check: the “clunk” test

Operate the door manually after disconnecting the opener. Listen for a “clunk‑clunk” as the rollers pass a certain spot. If the noise repeats at the same location, you likely have a flat spot or dent in the track that is obstructing the rollers. Minor clunks may be fixed with gentle hammering, but repeated binding after a repair suggests the track should be replaced.

4.3 Door balance and spring tension

A door that falls or springs upward suggests the tension system is failing. Often, track issues are secondary to Broken Garage Door Cables and Chain Off Track Issues. After pulling the emergency release, lift the door halfway and let go. If it falls or springs upward, the springs may be mis‑tensioned. Springs and cables are under high tension; never attempt to adjust them yourself. CaliforniaGarageDoorRepair warns that issues involving springs or slack cables are “pro‑only territory” and that you should call a licensed technician.

5 – Cost Comparison: Repair vs. Replace

Garage‑door track repair costs depend on the severity of the damage, whether you do it yourself or hire a professional, and your local service rates. The following estimates are drawn from CaliforniaGarageDoorRepair’s 2025 cost table and from service pricing in Richmond:

| Service | Typical cost (USD) | Description |

|---|---|---|

| DIY hammering | $0–$50 | Minor lip flares or shallow dents can be fixed using existing tools (rubber mallet, wood block, pliers). The primary cost is your time. |

| Service call/inspection | $75–$150 | A technician visit includes a safety check and tune‑up. Good for diagnosing track alignment issues without major damage. |

| Standard track alignment | $125–$250 | Adjusts vertical/horizontal tracks, tightens brackets and tests the door balance. Suitable for minor misalignment or small bends. |

| Bent track replacement (per side) | $150–$300 | Removes and replaces damaged track sections. Use this number when budgeting for a single vertical or horizontal rail. Replacement is necessary for kinked, creased or rusted tracks. |

| Full alignment + opener recalibration | $200–$350 | Comprehensive service including door and opener adjustment, photo‑eye alignment and full system test. |

| Major off‑track repair (Richmond) | $125–$200 | R&S Erection of Richmond notes that minor fixes like adjusting the track or realigning rollers cost around $125–$200, while serious damage requiring new rollers, tracks or springs can cost $150–$500. |

These costs may vary by location and door type, but they illustrate an important point: replacing a single track is much cheaper than replacing a door panel or the entire door. A severely bent track can cause the door to fall or crush a panel, resulting in hundreds (or thousands) of dollars of additional damage.

6 – Safety Steps Before You Start

Working on garage‑door tracks involves heavy weights and spring tension. Follow these safety guidelines before attempting any repair:

- Unplug the opener and disconnect the door. Pull the red emergency‑release cord and cut power to the opener so the door cannot move unexpectedly.

- Secure the door. Place C‑clamps or locking pliers on the track just above the bottom roller to keep the door from sliding down. R&S Erection of Richmond emphasizes using locking pliers to hold the door in place.

- Wear heavy gloves and safety glasses. Track edges can be razor‑sharp, and flying debris or springs can cause injury.

- Clear the area and provide lighting. Remove vehicles, bikes and clutter around the door and ensure you have bright light to see what you’re doing.

- Do not touch springs or cables. Torsion springs and cables carry extreme tension; loosening them can cause violent recoil. CaliforniaGarageDoorRepair warns to never loosen spring or cable hardware and to leave these parts to professionals.

- Know when to stop. If the track is severely damaged, if more than one roller has come out, or if you notice broken cables or springs, call a professional. Continuing to work on a compromised system can cause injury or further damage.

7 – Preventing Future Track Problems

Prevention is cheaper and safer than repair. Incorporate these habits into your maintenance routine:

- Tighten loose brackets and bolts. Vibration from regular use can loosen hardware. A quick check with a wrench keeps everything solid.

- Check track alignment regularly. Use a level to ensure that vertical tracks are plumb and horizontal tracks are level. Adjust small misalignments before they cause more serious issues.

- Clean the tracks. Wipe out dirt and debris. Avoid grease—it attracts dirt and makes the rollers stick.

- Lubricate rollers and hinges. A light silicone‑based lubricant on rollers and hinges reduces friction and helps the door move smoothly.

- Inspect for rust or corrosion. Catching rust early and treating it with rust remover can prevent the need for full track replacement.

Conclusion

Garage‑door tracks are the unsung heroes of the overhead‑door system. They support hundreds of pounds and allow the door to transition smoothly through a carefully engineered curve. Because of this, you should treat every bend or dent seriously. Minor flares and shallow dents can be repaired with gentle taps using a rubber mallet and wood block. However, once the steel is creased or the radius is twisted, replacement is the only safe option. Plastic deformation reduces the track’s load‑bearing capacity, and bending it back often hides cracks rather than restoring strength. If you’re unsure about the severity of the damage, err on the side of caution and contact a professional technician specializing in track repair and realignment near you —protecting your family and your garage door is worth more than the cost of a new track.